Stamped parts

We love precision!

Stamped parts

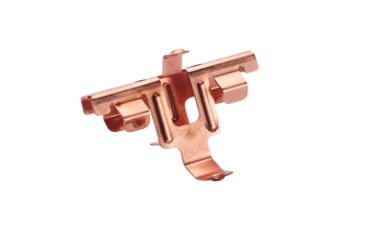

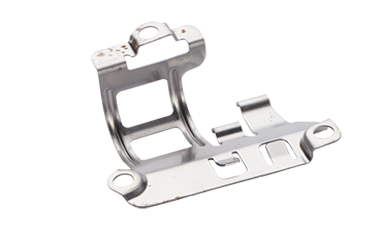

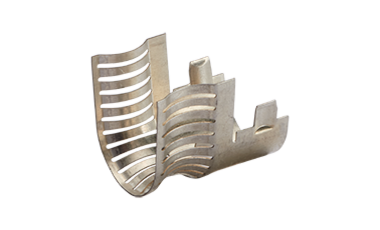

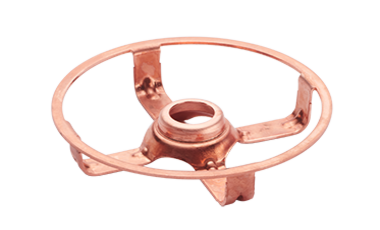

Our stamped-bent parts are used in automotive, information and communication technology, and also in medical engineering, electronics and electrical engineering. Traditional stamped-bent parts are contacts for connectors, switches or spring contacts for a wide range of applications. In control units, our stamped bent parts are used for example to take care of the power line function.

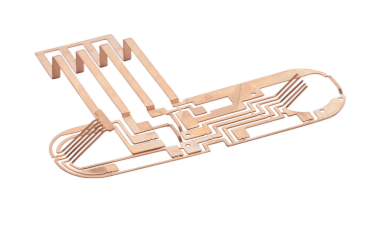

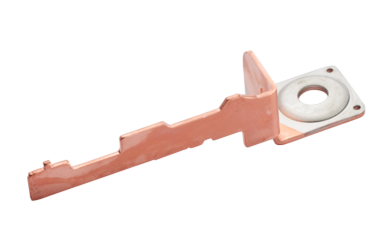

The parts we supply range from conductor rails of the most varied geometries and stamped-bent parts, which we ship as loose parts or on belts or strips depending on customer requirements, to complex lead frames, which we then continue to process using additional in-house procedures.

We are also happy to support you with contacts for which you take care of overmolding yourself. We can also manufacture stamped-bent parts as combination parts.

We process metals such as stainless steel, bronze, brass and copper with strengths of up to 1,500 N/mm², using both alloyed and unalloyed and bonded strips. The sheet thicknesses range from 0.05 to 2.5 mm.

Our stamping machines, manufactured by Bruderer, have a pressing force of 300 to 800 kN.

To guarantee the highest product quality, we design and build our tools ourselves, which means that we can achieve the best results in close coordination between design and production. The high levels of flexibility and determination of our employees also mean that we can respond extremely quickly to the wishes and requirements of our customers.

We package your stamped parts to your requirements in trays, tape & reels or as bulk material.

Our stamped-bent parts can be found in the following systems and assemblies:

- Electromechanical assemblies

- Control electronics

- Power electronics

- Window pane motors

- Wiper mechanisms

- Wire harness mounts

- Locking systems

- Industrial machinery robotics

- And much more

We can supply you with the following products.

Stamped strips at a glance

- Freeform stamped-bent parts

- Cylindrical bodies including sleeves

- Combination parts (welding in process)

- Conductor track contacts

- Braze connectors

- Spacers

- Cable holder clips

- Plug mouth pins

- Fixing elements

- Inserts for further processing

- Stamped strips with insulation displacement contacts

- Stamped strips with contact tracks

- Plug contacts

- Lead frames

- Bondable lead frames

- And much more

Our sleeves are used for example for pressing or injection into a plastic or metal housing as a cost-effective alternative to expensive turned and deep-drawn parts.

We process all common non-ferrous, aluminum, steel and stainless steel strips of materials, whether uncoated, selectively coated or stepped strips.

- All common non-ferrous, aluminum, steel and stainless steel strips of materials with tensile strengths up to 1,500 N/mm2

- Hot/cold-rolled grades (also with coating)

- Carbon steels (also pre-hardened)

- Stainless steels

- Non-ferrous metals and alloys

- Special alloys (e.g. magnetic soft iron)

- Tin-plated, silver-plated or gold-plated

- Individual surface finishing to customer specifications

- Roll-bonded AlSi

- Bondable strip surfaces

- Strip dimensions: Material thicknesses from 0.08 to 2.5 mm

- Bondable strip surfaces

Alloyed strips (own production) of gold, silver, nickel, tin, copper, palladium

- Washing/cleaning

- Testing/sorting

- Surface protection and/or

- Packaging including tape & reel

Highly sensitive camera measuring systems guarantee 100% control throughout the entire production process.

Contact

Product group: Stamped parts

Stefan Schach

Vice President of Sales Plastic Metal Composite

| Phone: | + 49 8650 9880-25 |

| stefan.schach@psm-protech.com |

Industry applications

Automotive

Electrical engineering

Precision engineering

Mechanical engineering and equipment manufacturing